MKQZ-V

features and uses

On the basis of fully complying with the requirements of Vapour Phase Polyethylene (VPE) process technology and design documents, Shanghai Leader has improved the original traditional system based on its own experience in catalyst application, and has carefully designed, developed and screened the process piping, equipment function, internal structure, system fine matching and facility accessories. This product is suitable for GPE, Univation and BP Vapour Phase Polyethylene process.

Get full product informationProduct Introduction

Product application:

On the basis of fully complying with the requirements of Vapour Phase Polyethylene (VPE) process technology and design documents, Shanghai Leader has improved the original traditional system based on its own experience in catalyst application, and has carefully designed, developed and screened the process piping, equipment function, internal structure, system fine matching and facility accessories. This product is suitable for GPE, Univation and BP Vapour Phase Polyethylene process.

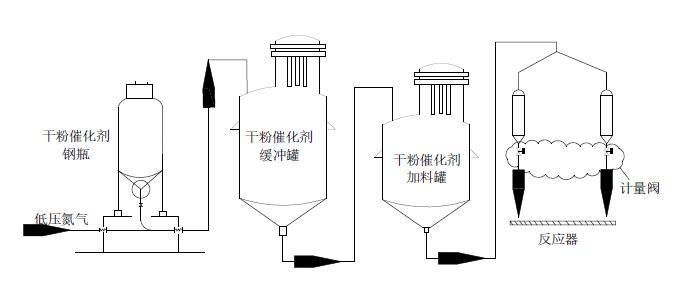

The dry powder catalyst is metered by means of an automatic 180° rotating metering ball valve. The frequency of rotation of the metering valve is adjusted to control the catalyst dosage.

During normal production, two injection metering valves are operated alternately and two dosing systems are designed, one for back-up use. During catalyst injection, the catalyst filling tank is operated full, the metering valve is filled with catalyst, the metering valve is turned 180°, and the dry powder catalyst is tipped and dumped into the corresponding blowing line, and then blown to the reactor by high-pressure blowing nitrogen.

Product characteristics:

1、Make up the shortcomings of traditional dry powder catalyst feeder which has the phenomena of sticking wall, bridging, poor fluidity, uneven filling, inaccurate metering and clogging;

Reduce the abrasion of catalyst particles and protect the morphology of particles;

3、Low input cost of the device, high economic efficiency;

4、Improve the stability and accuracy of catalyst charging;

5. Reducing the frequency of maintenance, saving cost for the device and improving the working efficiency.

PID:

Related Products

Product Message

沪公网安备31011602002448

沪公网安备31011602002448